| Working principle |

|

|

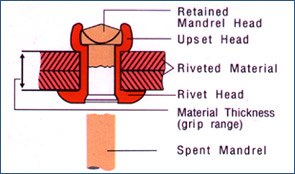

| Finally the mandrel reaches its predetermined break- load, with the spent portion of the mandrel breaking away and being removed from the set rivet. Fast, easy-to-use blind rivets offer speed of assembly, consistent mechanical performance and excellent installed appearance, making blind riveting a reliable and economical assembly method. |

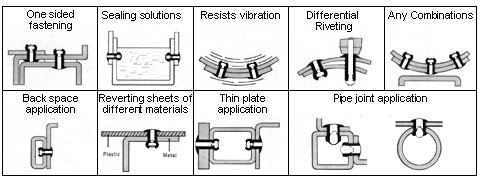

| Typical Applications |

Riveting

sheets of different materials

| Industrial Applications |

Transportation/Automobile/Equipments

Buses, Cars, Trucks,Trailers, Refrigeration / Containers, Airplanes, Sea / Air Containers, Ships, Material handling equipments etc…

Electrical - Electronics.

Computers, Telecom Equipments, Switching Equipments, Exchanges, Panels, Card Frames, Electronic Enclosures, Peripheral Terminal system devices, Cubicles, Lighting Equipments, any Sheet Metal Enclosures.

Consumer Electronics

Solar Systems, Medical Equipments, Washing Machines, Driers, Air- Conditioning Equipments, Elevators, Sign Boards, Steel Furniture, Various Tanks, Ovens, Kitchen Equipments and Systems. Kitchenware, Roofing, Dish Antennas, Industrial Ladders etc….

Buses, Cars, Trucks,Trailers, Refrigeration / Containers, Airplanes, Sea / Air Containers, Ships, Material handling equipments etc…

Electrical - Electronics.

Computers, Telecom Equipments, Switching Equipments, Exchanges, Panels, Card Frames, Electronic Enclosures, Peripheral Terminal system devices, Cubicles, Lighting Equipments, any Sheet Metal Enclosures.

Consumer Electronics

Solar Systems, Medical Equipments, Washing Machines, Driers, Air- Conditioning Equipments, Elevators, Sign Boards, Steel Furniture, Various Tanks, Ovens, Kitchen Equipments and Systems. Kitchenware, Roofing, Dish Antennas, Industrial Ladders etc….

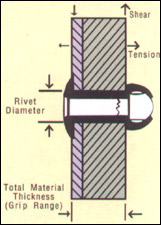

| Guide to select a rivet |

Select a Rivet based on strength required, corrosion resistance and materials to be joined.

Rivet material

The rivet material is decided on sheet materials to be joined

Aluminium : Medium strength generally used with aluminium sheets

All steel : this is used to join steel with steel sheets / plates.

All Stainless Steel : This is used to join stainless steel sheets or wherever corrosion resistance is required.

| Rivet head Rivet will bear on the sheet >> Dome Head. |

|

| Application requires flush surface >> Countersunk Head. |  |

| Rivet diameters Dia selection again depends in strength requirements. Rivet length This is decided on Grip rage. (see datasheet) Grip range Total thickness of material to be joined is called grip Range. This is an important factor as wrong Rivet length decided might effect the efficiency of joint. Case study A stainless steel fabrication calls for a joint strength of a 400 N - Shear and 700 N- Tensile, sheet thickness to be joined are 2 mm and 1 mm, Environment - Corrosive, Preferred diameter is 3.2 mm (see datasheet). Rivet to be used is stainless steel, Dome head, rivet size is 3.2 x 6.85 mm |

|

Recommended riveting tool - Pneumatic tool. Hand tool can also be used.

| Size range General sizes 3.2 ,4.0, 4.8 dia in mm. Also available 2.4 and 6.4 diameter rivets ( Lengths available to join grip range from 1.00 mm to 22 mm) |